When it comes to protecting your hands in dangerous environments, choosing the right glove can make all the difference. Cut resistant knit gloves offer an extra layer of protection against sharp objects and tools. But what makes them stand out in a sea of options? Let's explore.

Cut resistant knit gloves are specially designed to reduce the risk of injury from cutting or piercing hazards. Their construction uses materials like steel fibers or synthetic blends to provide strength while maintaining flexibility.

Cut resistant gloves are a must-have for industries like construction, warehousing, and manufacturing, where workers are frequently exposed to sharp tools or machinery. Let’s dive into the details to better understand their function, material, and more.

What is the highest cut resistant glove?

When safety is a priority, understanding the highest level of cut resistance is crucial. What makes a glove the "highest" cut resistant?

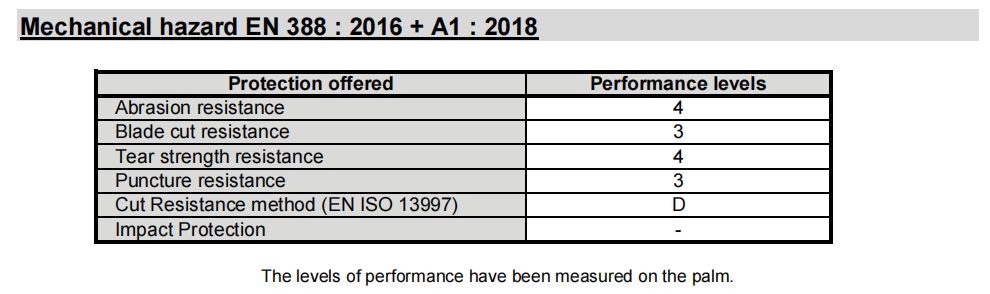

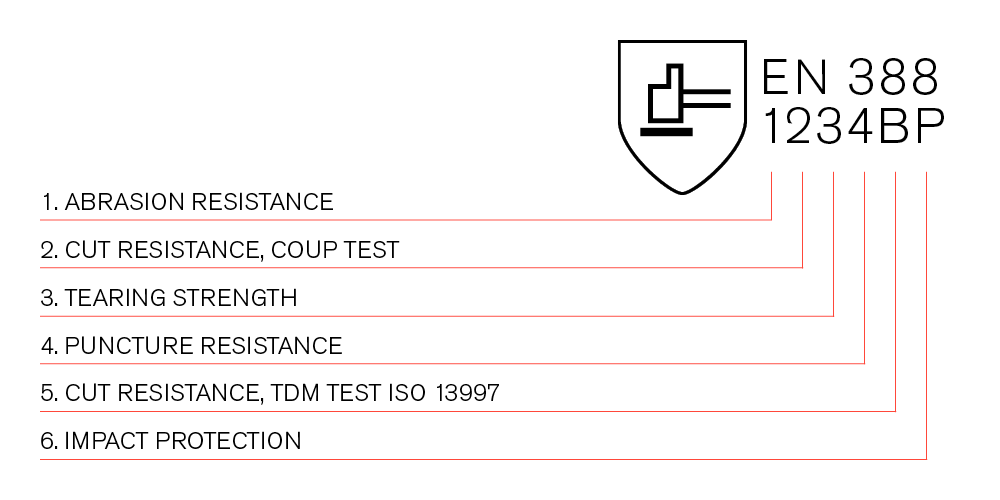

The highest cut resistant gloves are typically rated according to standards such as ISO 13997 (also known as the Coup Test). These gloves often feature high-performance materials like aramids, stainless steel, or ultra-high molecular weight polyethylene (UHMWPE).

Dive Deeper into Cut Resistance

The highest cut resistant gloves are classified based on their performance in standardized tests. The Coup Test measures the force required to cut through a glove, and gloves rated higher (Level 5 and above) offer the most protection. This is important for workers handling sharp tools, glass, or metal, where precision and protection are equally critical.

Understanding Cut Resistance Ratings

- Level 1-3: Low cut resistance, suitable for light tasks.

- Level 4-5: Moderate to high cut resistance, for medium-risk tasks.

- Level 6-9: Very high cut resistance, ideal for heavy-duty and high-risk environments.

What makes a glove cut resistant?

What exactly gives a glove its ability to resist cuts? The answer lies in the materials and design.

Cut resistant gloves combine various materials, like steel mesh or high-tech synthetics, with unique knitting techniques to enhance their strength and durability against sharp edges.

Cut resistant gloves often feature a blend of fibers designed to work together. Steel or fiberglass threads, for example, are interwoven into the fabric, significantly enhancing the glove’s ability to prevent cuts. It’s not just about materials; the thickness and tightness of the knit also contribute to the glove's overall strength.

Dive Deeper into Materials and Construction

Materials used in cut resistant gloves vary from standard to premium options. Steel mesh is often found in high-risk environments, while synthetic fibers like Dyneema provide excellent performance with a lighter feel. Some gloves even use a combination of these fibers to optimize both cut resistance and comfort.

Popular Materials:

- Kevlar®: Known for its strength and high cut resistance.

- Dyneema®: Light yet incredibly strong, offering high resistance against cuts.

- Stainless Steel: Often used in gloves for the highest level of protection.

What are nitrile gloves not resistant to?

Nitrile gloves are popular for their chemical resistance, but do they hold up well against cuts?

Nitrile gloves, though excellent for resisting punctures and chemicals, are not designed for cut resistance. They offer limited protection against sharp edges and can easily tear when exposed to cutting hazards.

Nitrile gloves are great for tasks involving chemicals, oil, or cleaning, but they’re not built to withstand the abrasive conditions that come with heavy cutting. If you're looking for cut protection, nitrile may not be the best choice, especially for tasks that require higher levels of defense.

Dive Deeper into the Limitations of Nitrile Gloves

Nitrile gloves are often chosen for their comfort, elasticity, and resistance to punctures. However, they have limitations when it comes to sharp objects. Tasks like handling sheet metal, glass, or knives would require gloves with specific cut resistance ratings, like knit gloves or gloves made with steel or aramid fibers.

Nitrile Glove Drawbacks:

- Puncture resistance: High.

- Chemical resistance: High.

- Cut resistance: Low.

What is the difference between A1 and A2 cut resistant gloves?

Understanding the distinction between A1 and A2 ratings is essential for choosing the right gloves for your needs. But what does each rating mean?

The difference between A1 and A2 cut resistant gloves comes down to the level of cut protection they provide. A2 gloves offer a higher level of protection than A1, making them suitable for more dangerous environments.

The ratings come from standardized tests where gloves are subjected to sharp objects and measured for their ability to resist cuts. A1-rated gloves provide basic protection, while A2-rated gloves offer more advanced defense.

Dive Deeper into A1 vs. A2 Ratings

In real-world applications, the choice between A1 and A2 gloves depends on the task at hand. A1 gloves might suffice for light assembly work, while A2 gloves are better suited for tasks where workers handle sharp tools or heavy machinery. Higher ratings, such as A3 or A4, offer even more protection, especially for those in heavy industry sectors.

A1 vs. A2 Gloves Comparison:

| Feature | A1 Gloves | A2 Gloves |

|---|---|---|

| Cut Resistance | Low to Moderate | Moderate to High |

| Suitable Tasks | Light assembly | Heavy-duty tasks |

| Material Strength | Basic synthetic | High-performance fibers |

Conclusion

Cut resistant knit gloves provide essential protection for workers exposed to sharp objects. By understanding ratings, materials, and limitations, you can make an informed choice that keeps your hands safe.

2 Responses