Industrial safety gloves are essential for protecting workers from various hazards. Yet, choosing the right glove can be overwhelming due to the many types available.

There are six main types of industrial safety gloves: disposable gloves1, fabric gloves2, leather gloves3, coated gloves4, chemical-resistant gloves5, and cut-resistant gloves6.

Each type serves a specific purpose and is designed for particular industries. Let me explain further.

How many types of safety gloves are there?

Safety gloves come in a variety of styles and materials, each tailored to specific applications. The options can feel endless.

Safety gloves can be categorized into general-purpose, task-specific, and industry-specific types, each addressing unique safety needs.

The six main types of safety gloves

Here’s a closer look at the six primary categories of industrial gloves:

1. Disposable gloves

- Made from latex, nitrile, or vinyl.

- Used in industries like healthcare or food handling.

- Protect against contamination but not durable.

2. Fabric gloves

- Woven or knitted material.

- Provide basic hand protection for light tasks, such as warehouse handling.

3. Leather gloves

- Offer durability, abrasion resistance, and grip.

- Commonly used in construction and heavy-duty work.

4. Coated gloves

- Feature a protective layer (e.g., nitrile or PVC).

- Used for grip, puncture resistance, or waterproofing.

5. Chemical-resistant gloves

- Protect against acids, solvents, and hazardous chemicals.

- Essential in chemical manufacturing or laboratory work.

6. Cut-resistant gloves

- Made with materials like Kevlar or metal mesh.

- Used in industries like glass handling or metal fabrication.

Table for quick comparison

| Type | Key Feature | Industry |

|---|---|---|

| Disposable gloves | Single-use, contamination | Healthcare, food handling |

| Fabric gloves | Light protection | Warehousing |

| Leather gloves | Abrasion-resistant | Construction, heavy industry |

| Coated gloves | Grip, waterproofing | Manufacturing |

| Chemical-resistant | Chemical hazard protection | Chemical, lab work |

| Cut-resistant gloves | Prevents cuts | Metal, glass industries |

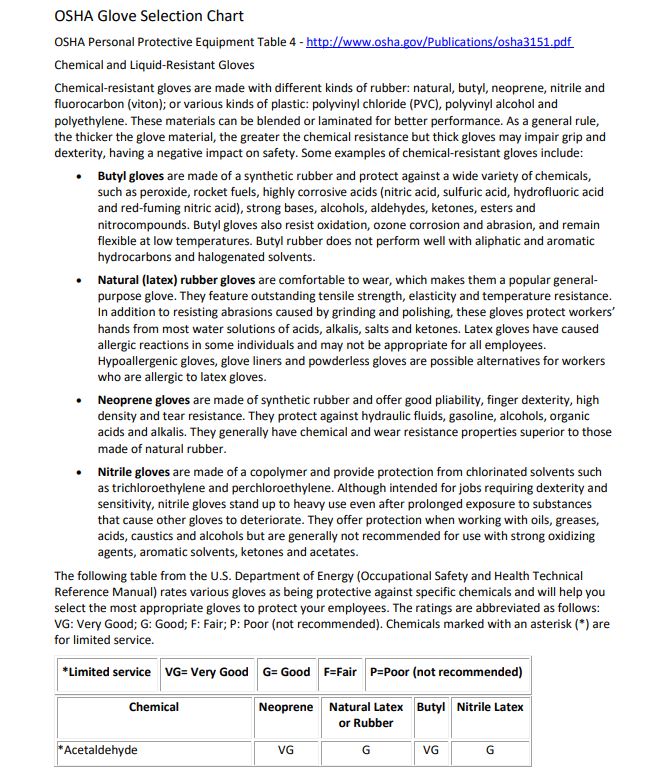

What type of gloves are recommended by OSHA?

The Occupational Safety and Health Administration (OSHA7) sets safety standards across industries, including guidelines for gloves.

OSHA recommends gloves based on the hazard type, such as chemical exposure, heat, or sharp objects. Employers must assess risks and provide suitable gloves.

How OSHA guidelines influence glove selection

OSHA does not endorse specific glove brands. Instead, it requires employers to conduct a hazard assessment under its Personal Protective Equipment (PPE8) standards. Here’s how it works:

Step 1: Identify hazards

Examples:

- Chemicals require chemical-resistant gloves.

- Heat hazards may need insulated gloves.

- Cut risks demand cut-resistant gloves.

Step 2: Match gloves to hazards

Employers must select gloves that meet the ANSI/ISEA 1059 standard, which classifies gloves based on performance (e.g., cut resistance, puncture resistance).

Step 3: Training workers

Employers are also responsible for educating workers on the correct use, care, and replacement of safety gloves.

For instance:

- Using nitrile gloves for chemical protection in labs.

- Opting for leather gloves for construction site work.

What are level 4 gloves?

If you’ve ever heard the term “level 4 gloves,” you may wonder what it means and when they are needed.

Level 4 gloves refer to cut resistance, offering a high level of protection against sharp objects.

Dive deeper: Understanding cut resistance levels

Cut resistance is measured under the ANSI/ISEA 105 standard9. Levels range from 0 to 9, with higher numbers indicating greater protection.

Key details about level 4 gloves:

- Level 4 is suitable for medium to high-risk tasks, such as handling sharp glass or metal sheets.

- Made from high-performance materials like Kevlar10, Dyneema, or metal mesh.

- Often used in industries like automotive, glass handling, and construction.

| Cut Resistance Level | Application |

|---|---|

| Level 1 | Light protection (e.g., packaging) |

| Level 4 | Medium-high risk (e.g., glass cutting) |

| Level 9 | Extreme protection (e.g., heavy metal) |

Level 4 gloves strike a balance between dexterity and protection, making them versatile for various industries.

What are category 3 gloves?

The term "category 3 gloves" refers to European Union (EU) PPE classifications. But what exactly sets them apart?

Category 3 gloves are designed to protect against high-level risks, such as irreversible harm or fatal hazards.

Dive deeper: What makes category 3 gloves special?

Under the EU regulation (EU) 2016/42511, PPE gloves are divided into three categories:

Breakdown of PPE categories:

- Category 1: For minimal risks (e.g., gardening gloves).

- Category 2: For intermediate risks (e.g., mechanical protection gloves).

- Category 3: For high risks (e.g., chemical, heat, or electrical hazards).

Features of category 3 gloves:

- Must be certified by a Notified Body to meet EU standards.

- Tested for protection against severe risks, like toxic chemicals, heat, or cuts.

- Often include markings for CE certification, showing compliance with strict safety tests.

| Category | Risk Level | Example Gloves |

|---|---|---|

| Category 1 | Minimal risk | Gardening gloves |

| Category 2 | Medium risk | Abrasion-resistant gloves |

| Category 3 | High risk (irreversible) | Chemical-resistant gloves |

If you’re exporting to Europe or dealing with hazardous industries, category 3 gloves may be required to comply with safety regulations.

Conclusion

Understanding the types of industrial safety gloves helps ensure worker safety across different industries. From cut-resistant level 4 gloves to category 3 PPE, each serves a unique purpose.

-

Explore leather gloves and their durability for heavy-duty work.

-

Discover the importance of chemical-resistant gloves in hazardous environments.

-

Understand how cut-resistant gloves protect against lacerations.

-

PPE (Personal Protective Equipment) guidelines for workplace safety.

-

ANSI/ISEA 105 standards for glove performance classification.

-

Kevlar material offers exceptional cut resistance for safety gloves.