Work gloves are essential for safety and efficiency in many industries. Choosing the right type can prevent injuries and improve productivity. But with so many options available, how do you know which ones to choose?

There are six main types of work gloves: disposable gloves, fabric gloves, leather gloves, coated gloves, impact-resistant gloves, and cut-resistant gloves. Each type is designed for specific tasks and hazards.

Let’s explore these glove types in detail and understand their applications. This will help you make informed decisions when selecting the right gloves for your work environment.

How many types of gloves are there?

Gloves come in many types, designed for different purposes. Understanding these types helps in selecting the right protection for specific tasks.

Work gloves can be classified into six major categories: disposable, fabric, leather, coated, impact-resistant, and cut-resistant. Each type provides different levels of protection.

1. Disposable Gloves

These gloves are made from latex, nitrile, or vinyl. They are used for short-term tasks requiring hygiene, such as medical work or food handling.

2. Fabric Gloves

Fabric gloves provide minimal protection and are mainly used for handling light materials or improving grip. Some have coatings for added durability.

3. Leather Gloves

Leather gloves are durable and protect against abrasions. They are commonly used in construction, welding, and heavy-duty work.

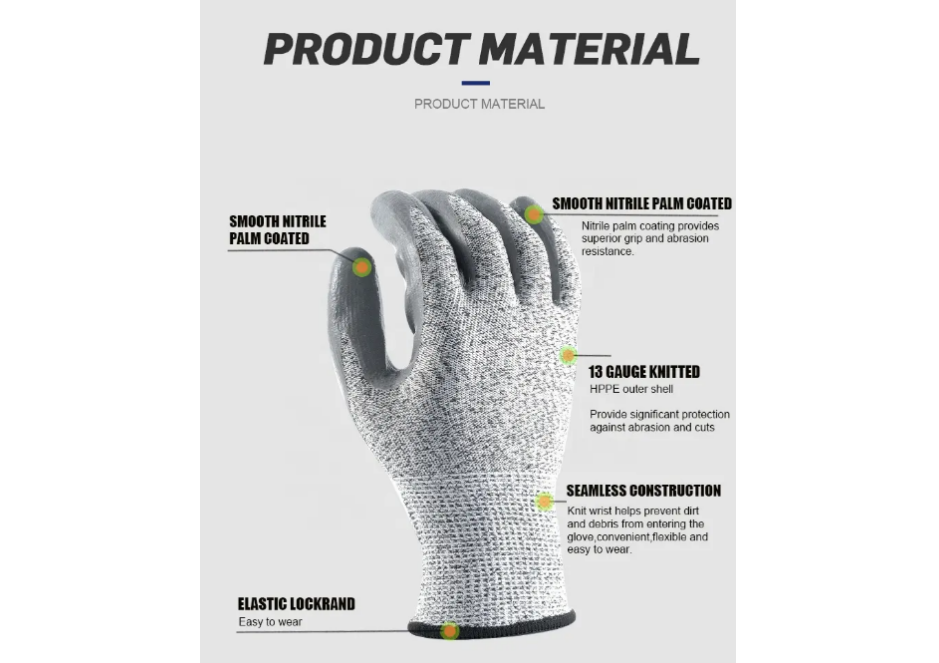

4. Coated Gloves

These gloves have a fabric base with coatings like nitrile, latex, or polyurethane. They offer good grip and protection against chemicals and punctures.

5. Impact-Resistant Gloves

These gloves have reinforced padding to absorb shocks. They are ideal for heavy machinery operations and industries with high-impact risks.

6. Cut-Resistant Gloves

Designed to prevent cuts, these gloves are made from materials like Kevlar or steel mesh. They are essential in glass handling and metalwork.

By understanding these types, businesses can ensure workers have the right gloves for their tasks, improving safety and efficiency.

What are category 3 gloves?

Some gloves are classified under specific safety standards to indicate their protection level. Category 3 gloves are one such classification.

Category 3 gloves provide the highest level of protection against life-threatening risks, such as chemical burns, extreme temperatures, and heavy machinery injuries.

Understanding PPE Categories

The European PPE (Personal Protective Equipment) Directive classifies gloves into three categories:

| Category | Protection Level | Example Usage |

|---|---|---|

| Category 1 | Minimal risks | Light cleaning, gardening |

| Category 2 | Intermediate risks | General industrial work |

| Category 3 | High risks | Chemical handling, extreme temperatures |

Applications of Category 3 Gloves

These gloves are crucial in industries dealing with hazardous materials, such as:

- Chemical Processing – Protection from corrosive substances.

- Firefighting – Resistance to extreme heat.

- Heavy Machinery Work – Prevention of severe injuries.

Choosing the right category ensures that workers remain safe in high-risk environments.

What are level 5 gloves?

Gloves are often rated by their cut resistance level. Level 5 gloves are among the highest-rated for protection.

Level 5 gloves offer maximum cut resistance and are designed for handling sharp objects, making them ideal for glass, metal, and construction industries.

Cut Resistance Levels Explained

The ANSI and EN 388 standards classify gloves by their ability to resist cuts. Here’s how they compare:

| Cut Level | Protection Level | Example Usage |

|---|---|---|

| Level 1-2 | Light protection | Assembly work, light handling |

| Level 3-4 | Medium protection | Automotive work, sheet metal handling |

| Level 5 | High protection | Glass cutting, heavy-duty metalwork |

Features of Level 5 Gloves

- Material: Often made with Kevlar, Dyneema, or stainless steel mesh.

- Durability: Withstands sharp edges and reduces injury risks.

- Grip: Some have coatings for better control in wet or oily conditions.

Level 5 gloves are essential for workers handling sharp materials daily, ensuring safety and efficiency.

Conclusion

There are six main types of work gloves, each designed for specific tasks. Category 3 gloves offer maximum protection in high-risk environments, while Level 5 gloves provide superior cut resistance. Choosing the right gloves ensures worker safety and efficiency.