Safety gloves play a crucial role in protecting workers from various hazards in different industries. From punctures to cuts and chemical exposure, these gloves are designed to provide maximum safety. But how many types of safety gloves are there, and which ones should you choose for your needs?

Safety gloves come in a variety of types, each tailored to specific hazards. The main types include cut-resistant gloves, chemical-resistant gloves, impact-resistant gloves, and heat-resistant gloves, among others.

As a worker, understanding the different types of safety gloves can make all the difference in preventing injuries and ensuring safety. So, let’s dive deeper into the different categories of safety gloves.

How many types of gloves are in safety?

Safety gloves vary greatly depending on the industry and specific risks involved. So, how do you decide which one is right for the job?

There are many different types of safety gloves, each designed for specific risks. For example, you’ll find cut-resistant gloves, chemical-resistant gloves, welding gloves, and electrical gloves.

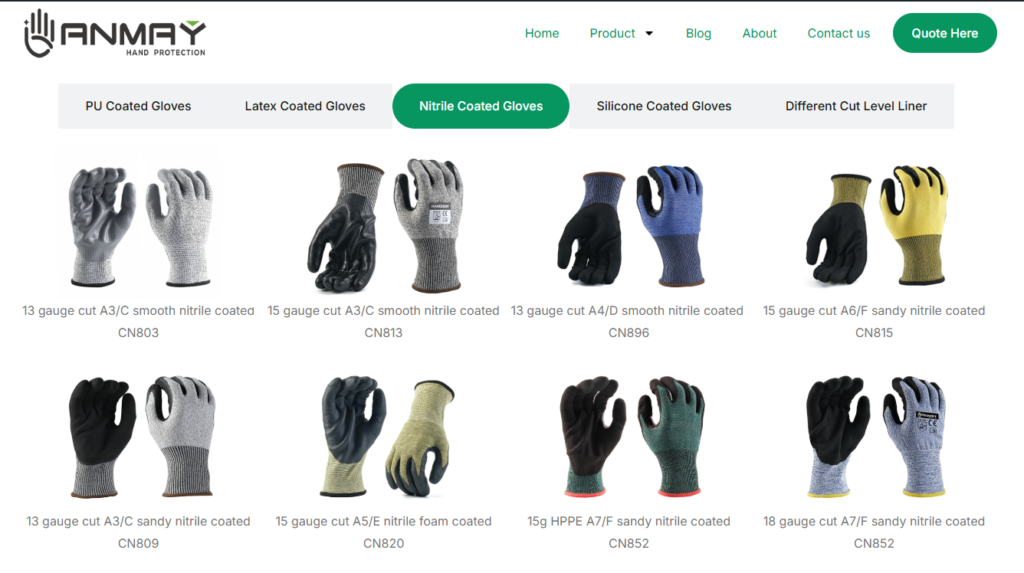

Cut-resistant Gloves

These gloves are designed for workers who handle sharp objects like glass, metal, or machinery. The material used to make these gloves is typically a mix of Kevlar, steel, and fiberglass, which makes them resistant to cuts and abrasions.

Chemical-resistant Gloves

These gloves are essential when handling toxic chemicals or solvents. Made from materials such as rubber, nitrile, and PVC, these gloves are designed to prevent the skin from being exposed to harmful substances.

Impact-resistant Gloves

For industries that deal with heavy machinery or tools, impact-resistant gloves are important. They have extra padding or hard materials that protect the hands from blunt force injuries or compression.

Welding Gloves

Welding involves extreme heat and sparks, so welding gloves are made with materials that resist high temperatures and protect the hands from burns.

Electrical Gloves

Used in the electrical industry, these gloves are designed to provide protection against electrical shock, with insulating materials that prevent contact with live wires.

What type of gloves are used for construction?

Construction workers are exposed to numerous hazards on the job, from sharp objects to heavy machinery. So, what gloves should they be wearing to ensure maximum safety?

Construction workers typically use work gloves designed for tough tasks. These include leather gloves, reinforced gloves, and impact-resistant gloves.

Construction gloves are generally made from leather, rubber, or synthetic materials to withstand tough conditions. Leather gloves are often used for handling rough materials like wood and metal, while reinforced gloves are preferred for tasks requiring a firm grip or protection from impact.

Moreover, certain gloves may come with padded palms and knuckle protection to prevent injuries from impact and friction.

Leather Gloves

Leather is durable and offers a good balance between protection and flexibility. It is the material of choice for handling rough tools and materials in construction, as it can prevent cuts and abrasions.

Rubber Gloves

For handling wet or oily materials, rubber gloves are often used. They provide a secure grip and prevent exposure to liquids that might cause skin irritation or injury.

What type of gloves are recommended by OSHA?

OSHA (Occupational Safety and Health Administration) sets strict guidelines on protective equipment. But which gloves does OSHA recommend for different work scenarios?

OSHA recommends gloves based on the specific hazards a worker faces. This includes cut-resistant gloves, chemical-resistant gloves, and gloves with high abrasion resistance.

OSHA’s glove recommendations are designed to minimize the risk of injuries, which can lead to long-term health problems. Workers should assess the nature of their tasks and choose gloves accordingly. For example, if a worker is handling dangerous chemicals, OSHA would recommend chemical-resistant gloves. If the task involves cutting or handling sharp objects, cut-resistant gloves are the best option.

Moreover, OSHA emphasizes the importance of ensuring that gloves are properly fitted and well-maintained to provide maximum protection.

Ensuring Proper Fit and Maintenance

A key factor in safety is the proper fit of gloves. Gloves that are too loose can cause accidents, while those that are too tight can restrict movement and cause discomfort. OSHA stresses the need for periodic inspections and replacement of gloves that show signs of wear.

What is the most common used gloves?

Safety gloves come in many varieties, but which ones are most commonly used across different industries?

The most commonly used gloves are general-purpose work gloves, typically made of leather or a blend of synthetic materials. They are versatile and can be used in various industries.

General-purpose gloves, which can be used across many industries, remain the most common due to their versatility and cost-effectiveness. These gloves usually feature a strong, flexible design that offers a balance of comfort and protection.

Versatility of General-Purpose Gloves

These gloves are used in everything from construction to light assembly work. They offer decent protection against abrasions and cuts, and their cost-effective nature makes them ideal for industries with high-volume glove usage.

Conclusion

To ensure safety, it’s crucial to choose the right type of glove based on the specific risks of the job. From general-purpose gloves to specialized types like chemical-resistant and cut-resistant gloves, the options are vast.