When working in hazardous environments, choosing the right gloves is crucial. The wrong gloves can lead to discomfort, poor performance, or even injuries.

To choose the right gloves, consider material, protection level, fit, and industry requirements. Prioritize safety, comfort, and durability to ensure optimal hand protection.

Many buyers struggle to select the best gloves due to the wide variety available. This guide will break down key factors to help you make the right choice.

How must gloves be selected?

Selecting gloves requires careful evaluation of risks and working conditions. The right gloves protect hands from hazards while maintaining comfort and dexterity.

Choose gloves based on hazard type, durability, grip, flexibility, and compliance with safety standards. Match the glove material to the specific risks involved.

Understanding glove materials

Different materials offer unique benefits. Here’s a breakdown:

| Material | Features | Best for |

|---|---|---|

| Nitrile | Chemical resistance, durability | Industrial, medical, food processing |

| Latex | High flexibility, good grip | General use, healthcare |

| Leather | Abrasion resistance, durability | Construction, welding |

| Cut-resistant fabric | Protection from sharp objects | Glass handling, metalwork |

Industry-specific requirements

Different industries require specific glove features. For example:

- Construction: Heavy-duty gloves with abrasion resistance

- Chemical handling: Nitrile or neoprene gloves for chemical protection

- Glasswork: Cut-resistant gloves to prevent injuries

Understanding these factors helps ensure the right glove selection for any job.

How do you determine the correct glove size?

Wearing the wrong size gloves affects performance and safety. A tight glove limits movement, while a loose glove reduces grip and protection.

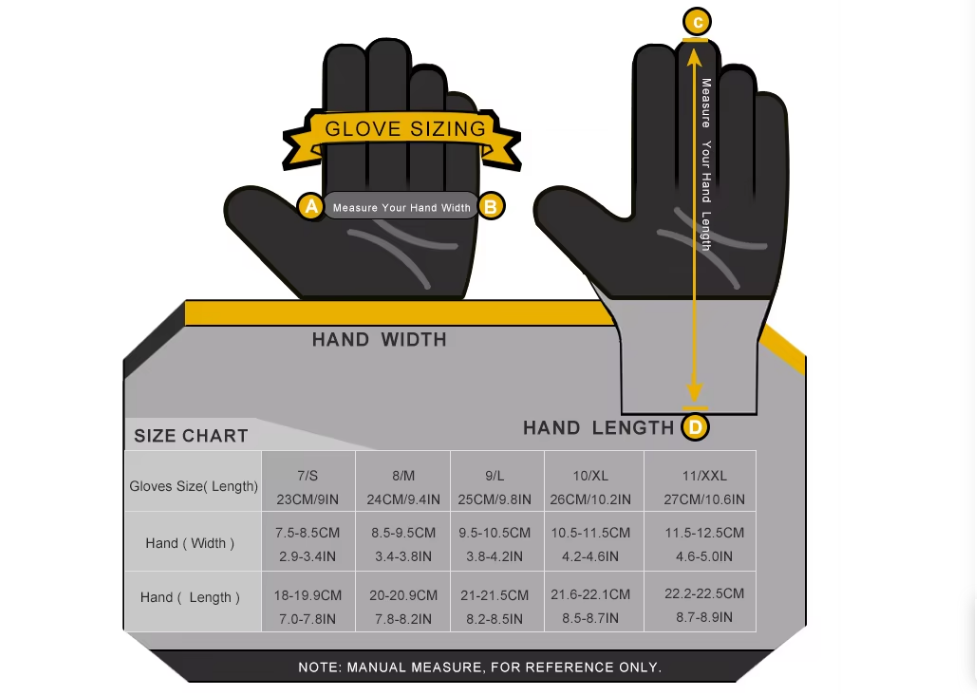

Measure hand circumference and length to determine the correct size. Use a glove sizing chart to match your hand measurements with the right fit.

Steps to measure glove size

- Measure hand circumference: Wrap a measuring tape around the widest part of your palm, excluding the thumb.

- Measure hand length: Measure from the tip of your middle finger to the base of your palm.

- Compare with a sizing chart: Different brands may have variations, so always check the manufacturer’s size chart.

Common glove sizing chart

| Size | Hand Circumference (inches) | Hand Length (inches) |

|---|---|---|

| S | 7-8 | 6.5-7 |

| M | 8-9 | 7-7.5 |

| L | 9-10 | 7.5-8 |

| XL | 10-11 | 8-8.5 |

Proper sizing ensures comfort, flexibility, and maximum protection.

How to choose the right size of gloves?

The right glove size enhances performance and prevents hand fatigue. A poorly fitted glove can lead to discomfort and reduced safety.

Try on gloves before purchasing, ensuring a snug but comfortable fit. Avoid gloves that are too tight or too loose for optimal hand protection.

Tips for choosing the right size

- Check flexibility: Fingers should move freely without restriction.

- Test grip: Ensure a firm but natural grip on objects.

- Wear for a few minutes: Prolonged wear should not cause discomfort or pressure points.

Adjusting for different glove types

Different materials fit differently. For example:

- Leather gloves may stretch over time, so consider a snug fit.

- Nitrile and latex gloves should fit closely without restricting movement.

- Cut-resistant gloves often have reinforced materials, requiring precise sizing.

A well-fitted glove improves safety, productivity, and overall comfort.

What glove specifications should you look for?

Selecting gloves involves checking key specifications to match workplace needs. Safety standards ensure that gloves provide the required protection.

Look for specifications like EN388 for cut resistance, ANSI standards, material composition, and intended use. Choose gloves that meet industry regulations.

Key safety standards

| Standard | Purpose |

|---|---|

| EN388 | Cut, abrasion, tear, and puncture resistance |

| ANSI/ISEA 105 | Cut resistance levels |

| EN374 | Chemical resistance |

| CE Certification | European safety compliance |

Additional glove features to consider

- Coating: Improves grip and durability (e.g., nitrile, polyurethane).

- Lining: Adds insulation for cold environments.

- Cuff style: Determines ease of removal and wrist protection.

By understanding these specifications, you can choose gloves that meet safety and performance needs.

Conclusion

Choosing the right gloves requires considering protection level, fit, and compliance with safety standards. A well-chosen glove enhances safety and comfort.