When you’re working on tough projects, the wrong gloves can lead to discomfort or even injury. Finding the perfect work gloves can protect your hands and enhance productivity. So, how can you make the right choice?

To select the perfect work gloves, consider your project’s needs, materials, and hazards. Choose gloves that balance durability, comfort, and safety certifications.

A pair of gloves may seem simple, but choosing the wrong one can lead to inefficiency and accidents. Keep reading to learn how to pick the ideal gloves for your specific tasks.

How to choose work gloves?

Picking the right work gloves is more than just a decision about size or color. It involves understanding your job’s risks, materials, and working conditions. Here's how to break it down.

To choose work gloves, identify hazards, select the correct material, and ensure compliance with safety standards like CE certifications.

Assessing workplace hazards

Start by identifying potential risks in your work environment. Common hazards include cuts, punctures, extreme temperatures, and chemicals. For instance, a warehouse worker lifting heavy boxes requires gloves with excellent grip and puncture resistance.

| Hazard Type | Recommended Material | Example Industries |

|---|---|---|

| Cuts and abrasions | Cut-resistant fibers (e.g., HPPE) | Glass handling, construction |

| Chemical exposure | Nitrile or PVC | Chemical plants, laboratories |

| High temperatures | Heat-resistant leather | Metalworking, welding |

Prioritize material and functionality

The material of the glove significantly impacts its performance. Latex-coated gloves offer excellent flexibility for general use, while nitrile-coated ones are ideal for oily or chemical-heavy environments. If you’re dealing with glass or sharp tools, opt for cut-resistant gloves made of Kevlar or HPPE.

Ensuring proper fit and comfort

Glove size matters. Ill-fitting gloves can cause accidents or discomfort. Use a size guide and try the gloves before purchasing if possible. Comfortable gloves with breathable liners improve usability during long shifts.

What kind of gloves should construction workers use?

Construction sites are full of hazards, from sharp tools to falling debris. The right gloves provide protection while maintaining flexibility for handling tools and materials.

Construction workers should use cut-resistant, anti-impact, and anti-slip gloves with a durable coating like nitrile or PU.

Protection against cuts and abrasions

Construction gloves should prioritize cut resistance. Tasks like handling rebar or sawing wood expose workers to sharp edges. Look for gloves with ANSI/EN cut-resistance levels A2 to A5.

Anti-impact features for heavy-duty tasks

On construction sites, hand injuries often occur from heavy equipment or falling objects. Anti-impact gloves with TPR (thermoplastic rubber) reinforcements on the backhand can absorb shocks and prevent injuries.

Grip and dexterity for tool handling

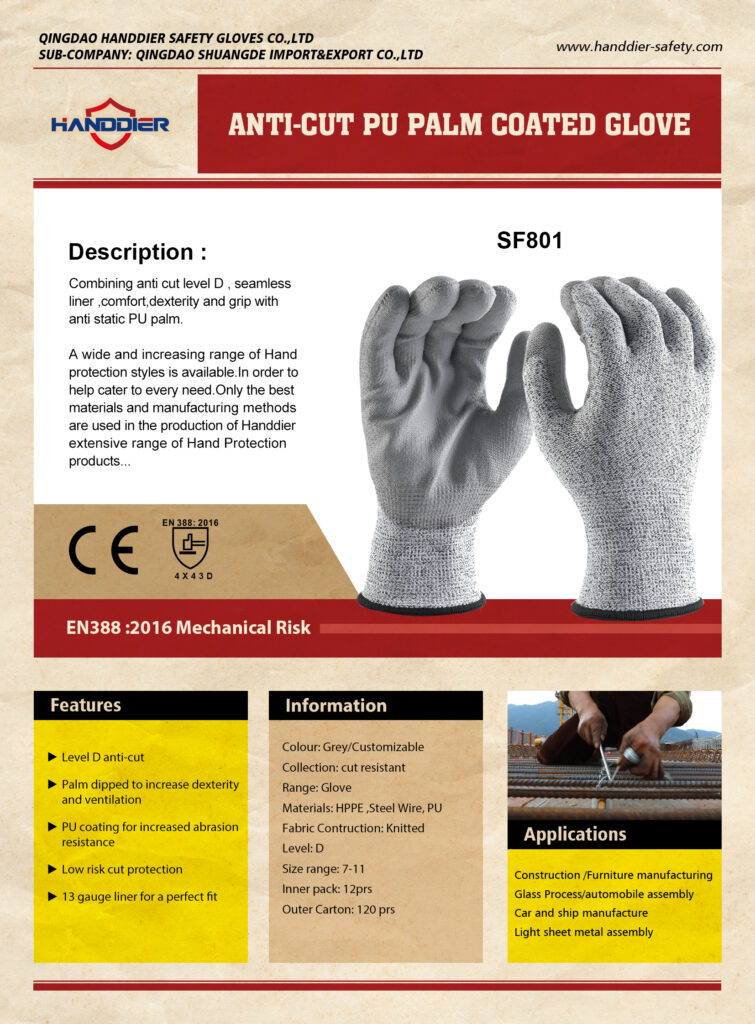

Many construction tasks require precision. Nitrile-coated gloves offer an excellent grip for handling tools or slippery materials. For intricate tasks, lightweight PU-coated gloves are a great choice.

How many main types of work gloves are there?

Work gloves are divided into several categories, each designed for specific industries and hazards. Knowing these categories simplifies the selection process.

There are six main types of work gloves: disposable, fabric, leather, coated, cut-resistant, and impact-resistant gloves.

The six main types of work gloves

Each type of glove serves a distinct purpose. Understanding these categories helps you match the glove to your project.

| Type of Glove | Features | Ideal Use Cases |

|---|---|---|

| Disposable | Lightweight, single-use | Medical, food handling |

| Fabric | Basic protection | Light tasks, gardening |

| Leather | Durable, heat-resistant | Welding, heavy-duty work |

| Coated | Enhanced grip and durability | Construction, warehouse work |

| Cut-resistant | High cut protection | Glass handling, metalworking |

| Impact-resistant | Shock absorption | Construction, heavy equipment |

Matching gloves to your job

For example, if you work in construction, coated gloves might be your daily go-to, while impact-resistant gloves are better for tasks involving heavy equipment. For a chemical lab, nitrile disposable gloves are essential.

Conclusion

Choosing the perfect work gloves involves understanding hazards, materials, and glove types. Prioritize safety, comfort, and functionality to protect your hands and enhance your productivity.

One Response

Your words possess both the lightness of a feather and the weight of wisdom — a rare and beautiful balance.