Are you confused about the standards that gloves need to meet in different industries? Understanding CE certification is critical if you want to ensure safety, compliance, and product quality.

CE certification standards for gloves define the safety and performance benchmarks that gloves must meet to be sold within the European Union. These standards ensure compliance with strict regulations.

Whether you're a supplier, a distributor, or a buyer, CE-certified gloves play a crucial role in ensuring workplace safety. Let me walk you through what CE certification means and why it matters for gloves.

What is the CE score on gloves?

The CE score on gloves often confuses buyers and suppliers alike. So, what exactly does it indicate?

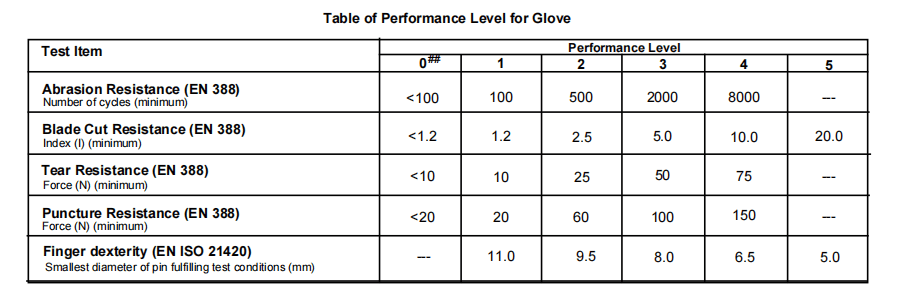

The CE score represents the glove's performance in various safety tests, such as abrasion, cut resistance, tear resistance, and puncture resistance, based on EN 388 standards.

CE scores are marked with pictograms and numerical ratings that describe how the gloves perform in specific areas. For example:

| Test Type | Score Range | Meaning |

|---|---|---|

| Abrasion Resistance | 1-4 | Higher numbers mean better durability |

| Cut Resistance | 1-5 | Indicates protection against sharp edges |

| Tear Resistance | 1-4 | Measures how resistant the glove is to tearing |

| Puncture Resistance | 1-4 | Evaluates resistance to punctures |

Understanding the pictogram:

The EN 388 pictogram is usually printed on the glove, showing numbers corresponding to these tests. For example, "4131" would mean the glove scored 4 in abrasion, 1 in cut resistance, 3 in tear resistance, and 1 in puncture resistance.

Why does the CE score matter?

These scores help you determine which gloves are suitable for specific tasks. For example:

- Construction workers need gloves with high abrasion resistance.

- Workers handling sharp tools require gloves with a high cut resistance rating.

What is CE certificate standards?

CE certification standards are not limited to gloves. They apply to a wide range of safety equipment. But for gloves, what makes them so essential?

CE certificate standards ensure gloves comply with EU regulations, focusing on safety, health, and environmental protection. They include various testing protocols under EN and ISO standards.

CE certification guarantees that gloves meet legal safety requirements to be sold in the EU market. Here's what the process involves:

- Testing: Gloves are tested under specific standards like EN 388 (mechanical risks), EN 374 (chemical risks), and others.

- Documentation: A Declaration of Conformity (DoC) must be provided by the manufacturer.

- Marking: The CE mark is then added to the product, certifying compliance.

Categories of gloves under CE certification:

CE certification divides gloves into three categories based on the risks they protect against:

- Category I (Minimal Risks): General-purpose gloves for low-risk tasks like gardening.

- Category II (Intermediate Risks): Gloves tested against specific risks such as cuts and abrasions.

- Category III (Complex Risks): Gloves offering protection against life-threatening risks like chemical exposure.

How do you verify CE certification?

Always check the CE marking, test reports, and the DoC. These are provided by manufacturers like Anmay Protective Tech, ensuring the gloves you purchase meet regulatory standards.

What are the ISO standards for gloves?

ISO standards are another layer of quality assurance. How do they differ from CE standards, and why are they important?

ISO standards for gloves focus on global quality management systems and uniformity in product safety and performance, ensuring consistency across international markets.

ISO standards often complement CE certifications by setting universal benchmarks. Key ISO standards for gloves include:

- ISO 13997: Measures cut resistance.

- ISO 9001: Ensures consistent quality in manufacturing processes.

Why ISO standards matter for exporters and importers:

If you're trading globally, ISO certifications help your gloves meet the requirements of multiple markets. For example:

- CE certification ensures compliance in Europe.

- ISO standards may be recognized in North America or Asia.

A deeper look at ISO 13997:

ISO 13997 introduces the "TDM Test," which measures the force required to cut through a material. This method offers a more accurate assessment than traditional EN 388 cut tests, especially for industrial gloves used in high-risk environments.

| Test Method | Key Feature | Purpose |

|---|---|---|

| Coup Test (EN 388) | Rotating blade cuts material | Measures cut resistance under low force |

| TDM Test (ISO 13997) | Straight blade cuts with force | Simulates high-risk scenarios |

By adhering to ISO standards, manufacturers like Anmay ensure that their gloves are not only compliant but also superior in performance.

What is the EN 374 standard for gloves?

EN 374 focuses on a critical area: chemical protection. How does it work, and why is it vital?

The EN 374 standard evaluates gloves for protection against chemicals and microorganisms, ensuring safety in high-risk industries like healthcare and chemical handling.

This standard tests gloves for:

- Chemical Permeation: Measures how quickly chemicals pass through the glove material.

- Chemical Penetration: Ensures no physical leaks or pores exist.

- Microorganism Resistance: Protects against viruses, bacteria, and fungi.

Common symbols in EN 374:

- Erlenmeyer Flask Icon: Indicates chemical protection.

- Microorganism Icon: Confirms resistance to microorganisms.

| Classification | Icon | Use Case |

|---|---|---|

| Type A (High Protection) | Erlenmeyer Flask + Letters | Extended protection against multiple chemicals |

| Type B (Medium Protection) | Erlenmeyer Flask | Protection against fewer chemicals |

| Type C (Basic Protection) | No additional letters | Minimal protection |

Why EN 374 matters for safety:

Chemical industries rely on this standard to ensure workers' safety. For example, gloves used in labs or factories handling hazardous materials must meet Type A requirements.

At Anmay, we manufacture gloves that comply with EN 374, offering customizable solutions for different industries.

Conclusion

CE certification standards for gloves ensure compliance, safety, and performance in a variety of applications. Understanding these standards, along with ISO and EN 374, helps you choose the right gloves for your needs.