When you work in environments where safety is key, every detail matters. The gloves you wear are no exception. But have you ever wondered why some gloves have a coating? Let’s explore the reasons behind it.

The coating on dipped gloves enhances their functionality by providing extra grip, durability, and protection, making them suitable for various industrial tasks.

Whether you’re handling sharp tools, slippery objects, or working in challenging conditions, coated gloves are designed to help. Keep reading to uncover more about their specific uses and benefits.

What are coated gloves used for?

Coated gloves are one of the most versatile types of hand protection. They are made to meet the needs of many industries and applications. But what makes them so effective?

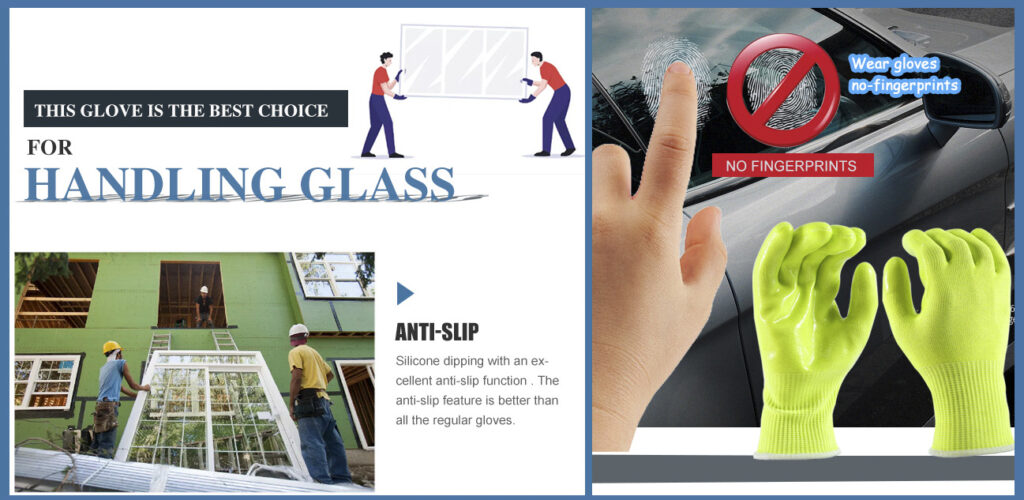

Coated gloves are commonly used for industrial tasks like construction, glass handling, and heavy-duty work where grip, cut resistance, and durability are essential.

Understanding the functionality of coated gloves

The coating material, often made of latex, nitrile, or polyurethane, serves a specific purpose depending on the work environment.

- Enhanced grip: A latex coating, for instance, provides superior grip in wet conditions, making these gloves perfect for construction or masonry work.

- Cut resistance: Nitrile coatings, on the other hand, are resistant to punctures and cuts, offering extra protection for glass handling or working with sharp tools.

- Chemical resistance: Polyurethane-coated gloves are lightweight and provide an added barrier against oil and chemicals, making them ideal for automotive or laboratory tasks.

| Coating Material | Key Benefits | Ideal Applications |

|---|---|---|

| Latex | Grip in wet/slippery conditions | Construction, gardening |

| Nitrile | Cut and puncture resistance | Glass handling, industrial tasks |

| Polyurethane | Oil and chemical resistance | Automotive, laboratory work |

As you can see, the type of coating is directly linked to the task at hand, ensuring workers get the protection they need.

What is the purpose of the plastic dipped coating on the handles of pliers?

Ever noticed the rubber or plastic coating on plier handles? It’s not just for looks. These coatings serve a significant purpose.

The plastic dipped coating on plier handles improves grip and insulates against electricity, providing both safety and functionality.

This small detail plays a big role, especially when working with tools in risky environments.

Beyond aesthetics – why handle coatings matter

The plastic or rubber coating helps to achieve two key benefits:

- Improved handling: The non-slip surface makes it easier to grip the tool, even in wet or greasy conditions. This minimizes the risk of accidents and ensures precision in work.

- Electrical insulation: Some coatings are designed to protect against low-voltage electrical currents, an essential feature for electricians or mechanics.

Although not all coated handles are electrically insulated, the ones that are can protect workers from dangerous shocks. Always check the specifications before relying on this feature for safety.

What is the purpose of powdered gloves?

Powdered gloves are a common choice in medical, food handling, and industrial settings. But why do some gloves include powder, and what does it do?

The powder in gloves reduces friction, making them easier to put on and take off, especially when hands are damp or sweaty.

This simple addition can save time and improve efficiency, but there’s more to know about its pros and cons.

Powdered vs. non-powdered gloves

The powder, typically made of cornstarch, has specific uses:

- Ease of use: Powdered gloves are ideal for situations where speed and convenience matter. They’re especially helpful for workers who need to switch gloves frequently.

- Moisture absorption: The powder helps absorb moisture, keeping hands dry during use.

However, powdered gloves are not without drawbacks. The powder can cause skin irritation for some users, and it may contaminate food or medical equipment. That’s why non-powdered gloves are often preferred in industries with strict hygiene standards.

What is a benefit of using coated fabric gloves as personal protective equipment?

Fabric gloves with coatings are a unique type of PPE. They combine comfort with protection, but what’s the real advantage?

Coated fabric gloves offer a balance of flexibility, grip, and protection, making them suitable for tasks requiring dexterity and safety.

The versatility of coated fabric gloves

Coated fabric gloves bridge the gap between lightweight, uncoated gloves and heavy-duty options. Their main benefits include:

- Flexibility: The fabric base ensures the gloves are breathable and comfortable for extended use. This is crucial for workers in manufacturing or assembly lines.

- Grip and durability: The added coating enhances grip while offering moderate protection against abrasions and cuts. This makes them ideal for tasks like light construction, painting, or warehouse work.

Real-world example: A warehouse scenario

In a warehouse setting, workers frequently handle boxes, tools, or machinery. Coated fabric gloves protect against minor cuts or abrasions while allowing the wearer to maintain a good grip. Plus, their lightweight design minimizes hand fatigue over long shifts.

| Feature | Advantage |

|---|---|

| Breathable fabric base | Comfort during extended use |

| Durable coated surface | Enhanced grip and abrasion resistance |

| Lightweight design | Reduces fatigue for repetitive tasks |

This combination of features ensures that workers can stay productive and safe without sacrificing comfort.

Conclusion

Coatings on dipped gloves and similar products serve to enhance safety, grip, and durability. Choosing the right glove or tool coating can make a big difference in performance and protection.