Work gloves are essential for safety, but not all gloves meet industry standards. Choosing uncertified gloves can lead to accidents, injuries, or legal issues. So, what certifications should work gloves have?

Work gloves should meet safety standards like CE (Europe), OSHA (USA), and ISO (global). These certifications ensure protection against risks like cuts, punctures, and chemicals.

Selecting the right gloves requires understanding certification standards. Let’s explore the key regulations that define glove safety worldwide.

What are the standards for work gloves?

Work gloves must comply with specific safety standards to protect users from hazards. Different regions have different regulations.

Key standards include CE (European safety compliance), OSHA (U.S. workplace safety rules), and ISO (global safety guidelines).

European Standards (CE)

In Europe, gloves must comply with EN 420, which sets general requirements like dexterity, comfort, and labeling. Other CE standards include:

| CE Standard | Protection Type |

|---|---|

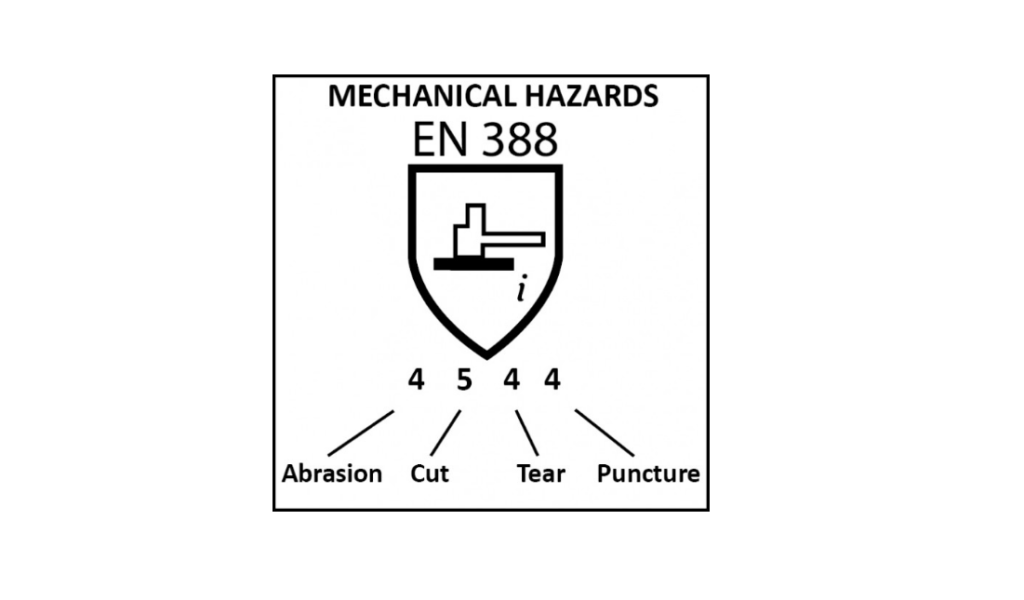

| EN 388 | Mechanical risks (cut, abrasion, tear, puncture) |

| EN 374 | Chemical and microbial resistance |

| EN 407 | Heat and flame resistance |

| EN 511 | Cold resistance |

U.S. Standards (OSHA & ANSI)

In the U.S., OSHA enforces workplace safety, while ANSI provides performance classifications:

- ANSI/ISEA 105: Defines cut resistance, abrasion, and puncture levels.

- 29 CFR 1910.138: OSHA regulation for hand protection in hazardous workplaces.

ISO Standards (International)

The ISO 21420 standard defines general safety requirements for gloves worldwide. ISO also covers specialized protection, like ISO 13997 for cut resistance.

Do gloves need CE certification?

CE certification is crucial for gloves sold in Europe, ensuring they meet safety standards.

Yes, gloves need CE certification if they are sold in the EU. CE marks show compliance with European safety regulations.

CE certification ensures gloves provide the protection they claim. Without it, gloves cannot legally be sold in Europe.

How to Check for CE Certification

CE-certified gloves have a CE mark and a four-digit number showing the notified body that tested them.

Why CE Certification Matters

- Legal Requirement: Essential for selling in Europe.

- Safety Assurance: Guarantees protection against risks like cuts and chemicals.

- Market Trust: Buyers prefer certified gloves for reliability.

What gloves are OSHA approved?

OSHA does not "approve" gloves but enforces safety rules that gloves must follow.

OSHA requires gloves to protect workers from specific hazards, following ANSI/ISEA 105 and CFR 1910.138 standards.

OSHA's Key Hand Protection Rules

OSHA mandates employers to:

- Assess workplace hazards to determine the right gloves.

- Select appropriate gloves for risks like chemicals, cuts, and burns.

- Train workers on proper glove use and limitations.

ANSI/ISEA 105: The U.S. Performance Standard

This standard defines levels of protection for:

- Cut resistance (Level A1 to A9)

- Abrasion resistance (Level 0 to 6)

- Puncture resistance (Level 1 to 5)

Employers must choose gloves that meet these standards based on workplace risks.

What is the ISO standard for gloves?

ISO standards ensure gloves meet global safety and performance criteria.

ISO 21420 is the main standard for protective gloves, covering general requirements like sizing, comfort, and labeling.

Key ISO Standards for Gloves

| ISO Standard | Focus Area |

|---|---|

| ISO 21420 | General requirements (fit, labeling, comfort) |

| ISO 13997 | Cut resistance |

| ISO 374 | Chemical protection |

| ISO 10819 | Vibration protection |

Why ISO Standards Matter

- Global Recognition: Accepted worldwide.

- Consistent Quality: Ensures gloves meet safety benchmarks.

- Industry Compliance: Used in manufacturing, construction, and industrial sectors.

Conclusion

Work gloves must meet safety certifications like CE, OSHA, and ISO to ensure protection against workplace hazards.